CNC Spindle Motors

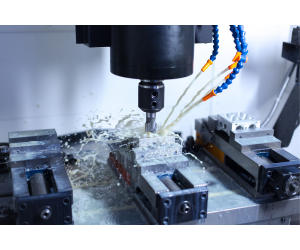

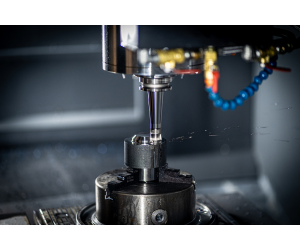

CNC spindle motors are essential for driving cutting tools or workpieces in CNC (Computer Numerical Control) machines, ensuring high precision, speed, and performance. They are widely used in industries such as metalworking, woodworking, and plastic cutting due to their ability to handle various materials and machining tasks.

Key features include:

CNC spindle motors enhance efficiency, versatility, and product quality, making them indispensable for modern machining processes.

Types of CNC Spindle Motors

| Type | Description | Speed Range (RPM) | Torque Range (Nm) | Cooling Method | Ideal Applications |

|---|---|---|---|---|---|

| AC Asynchronous (Induction) Motors | Operate using electromagnetic induction, commonly used for high-speed applications. | 1,000 – 24,000 | Low to Medium | Air-Cooled/Water-Cooled | Milling, Drilling, Grinding |

| DC Spindle Motors | Provide consistent torque and are commonly used in older CNC systems. | 500 – 6,000 | Medium | Air-Cooled | Low-Speed Machining |

| Brushless DC (BLDC) Motors | High torque, efficient, and suitable for high-precision applications. | 10,000 – 40,000 | High | Air-Cooled/Water-Cooled | High-Speed Milling, Engraving |

| Synchronous Motors | Maintain constant speed regardless of load variations, ensuring high accuracy. | 3,000 – 20,000 | Medium to High | Air-Cooled | Precision Machining, Engraving |

| Servo Motors | Provide precise control of position, velocity, and acceleration, used in high-accuracy tasks. | 5,000 – 60,000 | High | Air-Cooled | CNC Lathe, Milling, Robotics |

| Water-Cooled Motors | Use water circulation for cooling, ideal for prolonged high-speed operations. | 18,000 – 60,000 | Medium to High | Water-Cooled | Continuous Machining, High RPM |

| Air-Cooled Motors | Use air circulation for cooling, best for light to medium-duty operations. | 6,000 – 24,000 | Low to Medium | Air-Cooled | Light Machining, Hobby CNC |

Applications of CNC Spindle Motors

Benefits of CNC Spindle Motors

High Precision and Accuracy

Ensures consistent and precise machining, maintaining tight tolerances for complex operations.

Increased Speed and Efficiency

Operates at high RPMs, reducing production time and enhancing overall efficiency.

Versatility Across Materials

Suitable for machining metals, plastics, wood, and composites, offering flexibility.

Reduced Maintenance and Downtime

Built for durability, minimizing machine downtime and maintenance costs.

Improved Surface Finish

Delivers smooth, polished surfaces, reducing the need for post-processing.

Automation and Consistency

Integrates with CNC systems, ensuring repeatable results with minimal human intervention.

CNC Spindle Motors

Chamunda CNC is a trusted manufacturer and supplier of CNC spindle motors designed for high-precision machining across various industries. Our spindle motors are known for their robust construction, superior speed control, and smooth performance, making them ideal for CNC applications that demand accuracy and consistency.

What is a CNC Spindle Motor?

A CNC spindle motor is the core component of any CNC machine, responsible for rotating the cutting tool with high speed and torque. The motor’s performance directly impacts machining quality, cutting speed, and tool life. At Chamunda CNC, our spindle motors are designed to meet these critical requirements with exceptional efficiency.

Key Features of Chamunda CNC Spindle Motors

Our CNC spindle motors stand out in the market due to the following advanced features:

High-Speed Performance

Designed to deliver high RPM, our motors ensure fast, accurate, and clean cuts on a variety of materials, from metals to composites.

Low Noise & Vibration

Each motor is precisely balanced to minimize vibration and reduce operational noise, enhancing both tool life and workplace comfort.

Long-Lasting Durability

With high-quality bearings, rigid housings, and advanced cooling mechanisms, our motors are built to perform in demanding industrial environments.

Customizable Options

We offer customized spindle motor solutions tailored to your CNC machine requirements, including variable speed options and different mounting types.

Applications Across Industries

Chamunda CNC spindle motors are versatile and suitable for a wide range of industrial and commercial applications, including:

-

Automotive Part Manufacturing

-

Aerospace Component Fabrication

-

Metalworking and Milling Operations

-

Furniture and Woodworking

-

Plastic Molding and Prototyping

Our motors are compatible with various CNC machines such as routers, lathes, engraving machines, and milling machines.

Why Choose Chamunda CNC?

At Chamunda CNC, we combine cutting-edge engineering with a commitment to quality and performance. When you choose our spindle motors, you benefit from:

-

High-precision engineering for maximum output and efficiency

-

Stringent quality checks for each product

-

Expert technical support to help with installation, maintenance, and customization

-

Affordable pricing without compromising on quality

Our goal is to help manufacturers and machinists increase productivity while ensuring long-term reliability and performance.

Contact Us for CNC Spindle Motor Solutions

Whether you’re upgrading your existing CNC machine or building a new setup, Chamunda CNC has the right spindle motor for your application. Reach out to our team to explore the full range of products or request a custom-built CNC spindle motor tailored to your operational needs.

Enhance your machining accuracy and efficiency — choose Chamunda CNC spindle motors today.